Concrete Tomography Scanning

Ultra Sonic Pulse Echo (MIRA)

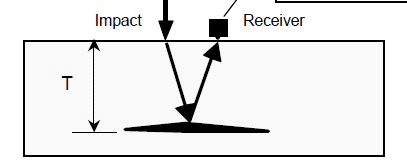

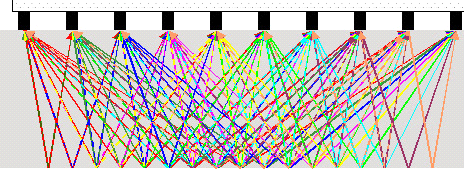

Concrete Tomography Scanning or the Ultrasonic Shear-wave Tomography technique (MIRA) represents a revolutionary approach to concrete ultrasonic. MIRA is an ultrasonic tomography device that can be used to diagnose subsurface concrete condition using an array of dry point contact (DPC) “touch-and-go” transducers (doesn’t require surface preparation). Each transducer can both transmit and receive low frequency (55 khz) shear waves. The DPC transducers provide the necessary consistency of impact and wavefront penetration for diagnostics up to 3 ft deep for typical concrete surface textures. MIRA incorporates 10 channels each comprised of 4 transducers in a multi-static array. This linear array allows for 45 transmitting and receiving pair measurements in each approximately 1 second scan that can be applied at a high productivity (unlike the traditional ultrasonic methods, which typically produce one pair of waves per measurement).

Concrete Tomography Scanning device, MIRA, can be used for the following applications:

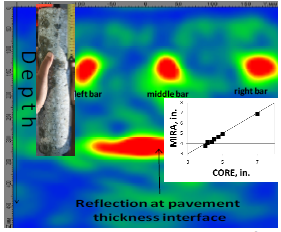

- Thickness: Concrete thickness estimation up to 3 feet deep with high accuracy

- Reinforcement location: Accurate estimation of reinforcement depth

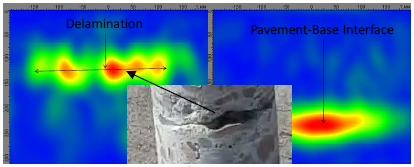

- Delamination/debonding: Detection of cracking in the PCC layer or de-bonding between PCC layers.

- Joint diagnostics: Detection of concrete deterioration, dowel position, spalling, etc. at PCC joints.

- Flaw detection: Defect/honeycombing/poor consolidation detection/ mud balls

- Material properties: Diagnostics of relative PCC strengths or asphalt compaction level

1 pair per measurement

45 pair per measurement (MIRA)

45 pair per measurement (MIRA)MIRA Visual Output Examples

Delaminating (left) and sound concrete (right).

The MIRA uses a low-frequency linear ultrasonic antenna array to produce high resolution tomographical images of

The MIRA uses a low-frequency linear ultrasonic antenna array to produce high resolution tomographical images ofconcrete.The MIRA is suitable for imaging of the internal structure of objects constructed of concrete and reinforced concrete

using pulse-echo technique of testing. This technique only requires access to one-side of the object in order to search

for foreign inclusions, holes, flaws, cracks, honeycombs, positioning of ducts and other inside the material and also

to assess the state of reinforcement bars in concrete.

Features

Real-time Imaging of the internal structure of the object- for easier understanding of testing results. Focusing antenna array of 48 elements (DDF-principle) – better resolution and higher sensitivity of the system, at that the focusing in every point of volume is provided.

Automatic calibration on the object

Automatic measurement of average ultrasonic velocity in the object Compensation of surface SH-wave providing clearer image in near surface area

Description of the system. The MIRA consists of 12 measuring units, combined into a focusing antenna array. Also included in the probe array is a control unit, data collection unit and internal computer for initial processing. Each measuring unit consists of 4 low-frequency broad-band DPC transducers with the nominal operation frequency of 50 kHz, These produce shear waves using only a dry point contact. The transducers have wear-resistant ceramic pins,which prolongs the lifetime of the transducer even when operating on rough, unprepared surfaces. Each transducer features an independent spring load, which allows performing testing on uneven surfaces with 100mm of travel in each transducer. A PC with the IDEAL Viewer software, can be used to create 2D or 3d Images of the collected tomographic scans scans. Data acquisition from antenna array received at one position of the array is an accumulation of signals collected from every pair of measuring units of antenna array.

https://www.yellowpages.com/daytona-beach-fl/mip/ema-structural-milestone-inspection-engineers-570512615

https://www.facebook.com/p/EMA-Engineers-40-Year-Structural-Inspections-100070363869893/?paipv=0&eav=AfauahGGS3eh4be2xYJDeqOn6mw_gp-EpaTiKMzF4jdf_xUBbEtx1hv5HhbSzaozI8g&_rdr